Renewable energies are conquering the energy market and helping the world to decarbonise. In most places of the world, wind or photovoltaic energy is the cheapest way to generate electricity. This electricity is, however, inherently volatile.

Despite direct usages of electricity, e.g. in heat pumps or electrified mobility, and short-term storage options by the way of emerging battery technologies that can store power economically for hours up to one day, there remains an urgent need for:

i) high energy density and transportable storage media, compatible with existing infrastructure,

ii) storage periods from days, weeks up to years (seasonable storage).

Renewable energy entering the future energy system will first be directly used and then chemically stored. All these technologies need to be developed, validated, optimised and scaled.

Renewable energy entering the future energy system will first be directly used and then chemically stored. All these technologies need to be developed, validated, optimised and scaled.

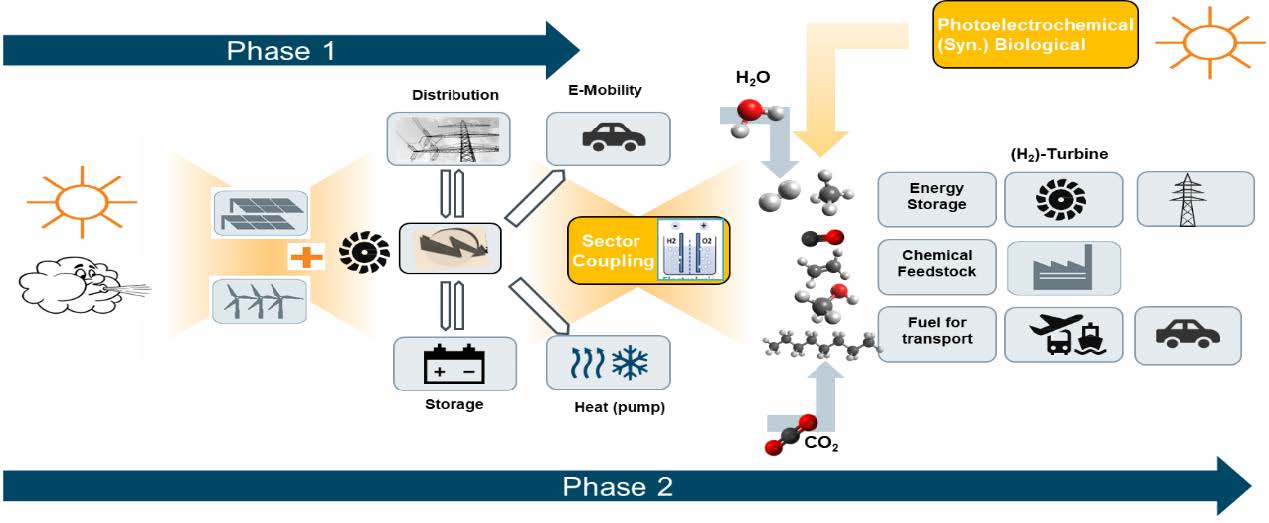

The transfer of renewable electricity to renewable compounds described in Figure above is called sector coupling. Ideally, it delivers a fuel that is composed of liquid hydrocarbons to achieve the highest possible energy density and that is compatible with classical fuel as a blend-in (or, in a later stage, as replacement – “drop-in”) and with the existing infrastructures. On the market, a tremendous demand for liquid hydrocarbon fuels will remain in the short to long-term future. Even in road transport, where viable technology options for electrification are already in the ramp-up phase segments like long-distance and heavy-duty transport still will rely on high energy density fuels. For important sectors as maritime shipping and especially aviation, viable alternatives to internal combustion engines are not visible.

As mentioned, renewable electricity will become increasingly affordable, but it will not come for free. The key challenge is to discover and optimise the most efficient way to source the input molecules and to transform the electrical energy into energy-dense chemical bonds. Approaches using photo-electrochemistry or algae constitute valuable possible routes from fundamental research, however, it will be difficult to reach the decarbonization goals of the European 2030 climate & energy framework on time with these technologies.

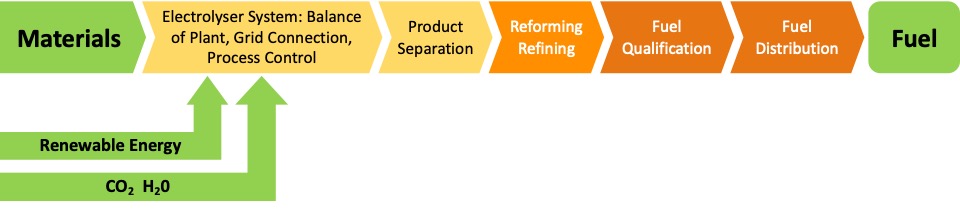

To rapidly approach the EU’s and the world’s climate targets, we need to build on the availability of concentrated renewable electricity and utilise electrolysis as the natural entry point of electricity into the chemical and fuel sector, thus realizing the overall process:

CO2 + H2O -> Hydrocarbons + O2

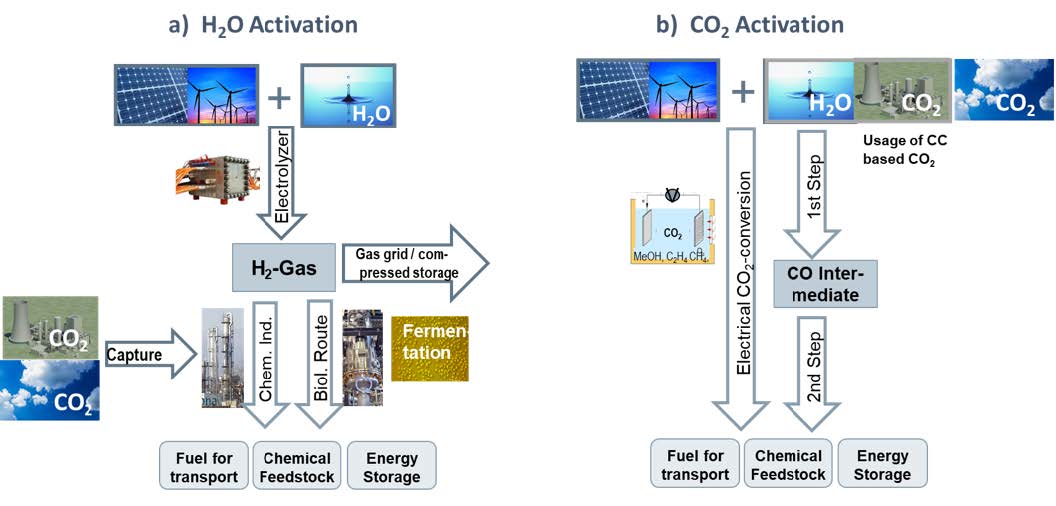

The conventional design of the electrochemical approach is shown in Figure below: It uses H2O activation via water electrolysis to produce hydrogen, which is then further processed downstream by thermo-catalytic means to obtain hydrocarbons. Water electrolysis is capable of generating H2 with a reasonable efficiency: using a modern PEM-type electrolyser, 70% or higher can be reached on the system level. This can even be exceeded if non-scalable prototypes of a solid electrolyte electrolyser are used. However, H2 needs to be processed further downstream and the overall process chain ends up with an efficiency of about max 40%. Given that, electricity is generated using state-of-the-art PV with an efficiency of 20% in the field, the solar-to-molecule efficiency is 8%. This needs to be improved upon.

Two main approaches to convert renewable electricity, CO2 and water into hydrocarbons are conceivable. They are

characterised by using electrochemistry to activate the water or to co-activate water and CO2. a) classical technologies, b)

EcoFuel CO2 activation process chain to achieve higher efficiency.

EcoFuel Objectives and targeted results

The objective of the EcoFuel project is therefore to develop, demonstrate and, in the long run, bring into production a new process for the generation of drop-in fuel, which will achieve a higher efficiency along the process chain compared to the classical process route via H2, thus saving primary energy, resources and cost, see Figure below . Additionally, characteristic/ specification in view of low emission of the new generated fuel is one major side aspect which will be addressed One base technological idea is to directly co-activate the CO2 together with water in a combined electrochemical process, so as to:

-

- better realise the full potential of efficient electrochemistry over the process chain,

- improve the dynamics/agility of the process in order to quickly adapt to the intermittent availability of renewables,

- reduce the number of transformation steps to intensify the process chain.

The EcoFuel Project will set-up a novel complete process chain, based on the power of electrochemistry to deliver truly green (CO2 neutral) fuels with an unprecedented overall energy efficiency (Figure below). The implementation of this new process chain that has the potential to boost the electricity-to-liquid hydrocarbon fuel molecule efficiency from ca 40% to a final value in optimised industrialisation of 54%, thus saving huge amounts of valuable renewable energy for the future mass production of CO2 neutral green fuels, while keeping the required newly installed renewable electricity capacity in the future at a manageable level.

The objective of the EcoFuel Project is a complete process chain based on the power of electrochemistry to deliver

The objective of the EcoFuel Project is a complete process chain based on the power of electrochemistry to deliver

truly green (CO2 neutral) fuels with an unprecedented overall energy efficiency.

The EcoFuel project, the integrated EcoFuel process, and its design parameters have the following overall conceptual goals:

-

- Answer the question of how the starting molecules can be sourced. This relates to water as well as to captured CO2 from unavoidable concentrated sources as well as direct air capture (DAC) of CO2.

- Design, build, validate, demonstrate a full input process flow, including the purifying of said inputs prior to feeding to the process (remove catalyst poisons), as well as addressing the CO2 concentration during electrolysis.

- Design, build, validate, demonstrate a new, highly effective, stable electrocatalytic process concept that directly converts CO2 into C2+ intermediate products. The Electrolyser system and its process needs to follow an industrially relevant design (100s of cm2 active electrode area) with high productivity of up to 1A/cm2, a continuous operation of at least one year with minimal maintenance at moderately elevated temperatures.

- Design, build, validate, demonstrate output process flow, where exit products from the electrolyser are separated, enriched, and purified.

- Design, build, validate, demonstrate cascading downstream conversion of separated electrolysis products to liquid fuel or fuel precursors, whereby standardised fuel properties can be guaranteed.

- Demonstrate the economic advantages of the EcoFuel Process

- Perform a Life Cycle Assessment (LCA) of the EcoFuel Process to demonstrate its sustainability and truly green nature, while minimizing or eliminating the use of rare and toxic materials.

Demonstrate sufficient load and feed flexibility of the overall EcoFuel process chain commensurate with intermittent renewable electricity generation.

The rising share of solar- and wind-based renewable electricity worldwide beyond the current capacity of the electrical grids generates serious large-scale electrical energy storage needs. To remedy this electricity storage challenge, scalable “Power-to-X” technologies are needed that enable the coupling and integration of different sectors, such as electricity, heat, mobility, and industrial production. The coupling of renewable electricity and mobility is of particular importance. Electromobility concepts for light-duty vehicles and applications allow for significant reductions of CO2 emissions thanks to direct electricity storage in battery vehicles. However, several important transport modes, such as aviation, maritime shipping, long-distance heavy-duty transport will remain critically dependent on high energy-density, hydrocarbon-based liquid fuels in the future. In order to cut carbon dioxide emissions also in these transport sectors and, at the same time, comply with the new EU RED II directive, admixtures of synthetic carbon-neutral liquid hydrocarbon fuels will be indispensable. This is why the efficient and sustainable production of synthetic, carbon-neutral, high energy density liquid hydrocarbon fuels from renewable electricity, water and CO2 has become a technology development priority.

The EcoFuel project concept centers on the integration of a set of chemical process steps into a complete process chain for the generation of renewable, high-energy density liquid hydrocarbon fuels for mobility applications. The process steps include feed supply, purification, as well as electro-catalytic and thermo-catalytic conversion processes.

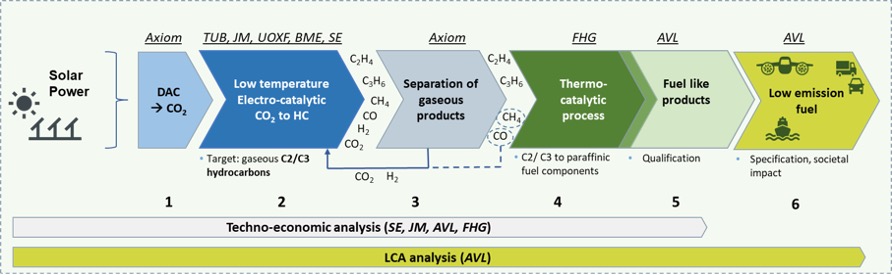

The individual EcoFuel process steps involve the electro dialysis-based concentration of atmospheric CO2, which, together with water and renewable electricity, is electrochemically converted into olefinic and paraffinic gaseous hydrocarbon molecules (such as ethylene, ethane, propylene, propane, acetylene, and possibly others), followed by their separation and subsequent thermo-chemical reactive conversion into renewable liquid C6+ hydrocarbon fuels suitable for use in combustion engines.

The figure below illustrates the EcoFuel process concept in more detail.

The EcoFuel Process Chain. The integrated DAC/electro-catalytic/thermo-catalytic fully carbon-neutral, renewable “Atmospheric CO2/Power-to-liquid fuel” process chain concept in the project EcoFuel. Each process step (1-6) and the overall process will target a final TRL 4-5 prototype demonstrator in a laboratory environment. The demonstrator will be run sufficiently long to generate liquid fuel products in the 100ml range. The Acronyms denote the consortium partners involved in each process step. The chemical species shown illustrate the target molecules for the process chain, as well as the recycled products.